Alumina Ceramic heaters were developed based on ceramic lamination technologies, which are mainly used for highly reliable IC ceramic packages. Thus, these are widely used in electronic tools.

Material performance

Material: 95% Alumina

Maximum operation temperature: 1000℃

Thermal conductivity (20℃): 18W/(m.K)

Specific heat (20℃): 0.78×103J/(kg.K)

Coef.of linear thermal expansion (40~800℃)

Vickers hardness (Load 500g): 12.3 Gpa

3-point flexural strength: 340 MPa

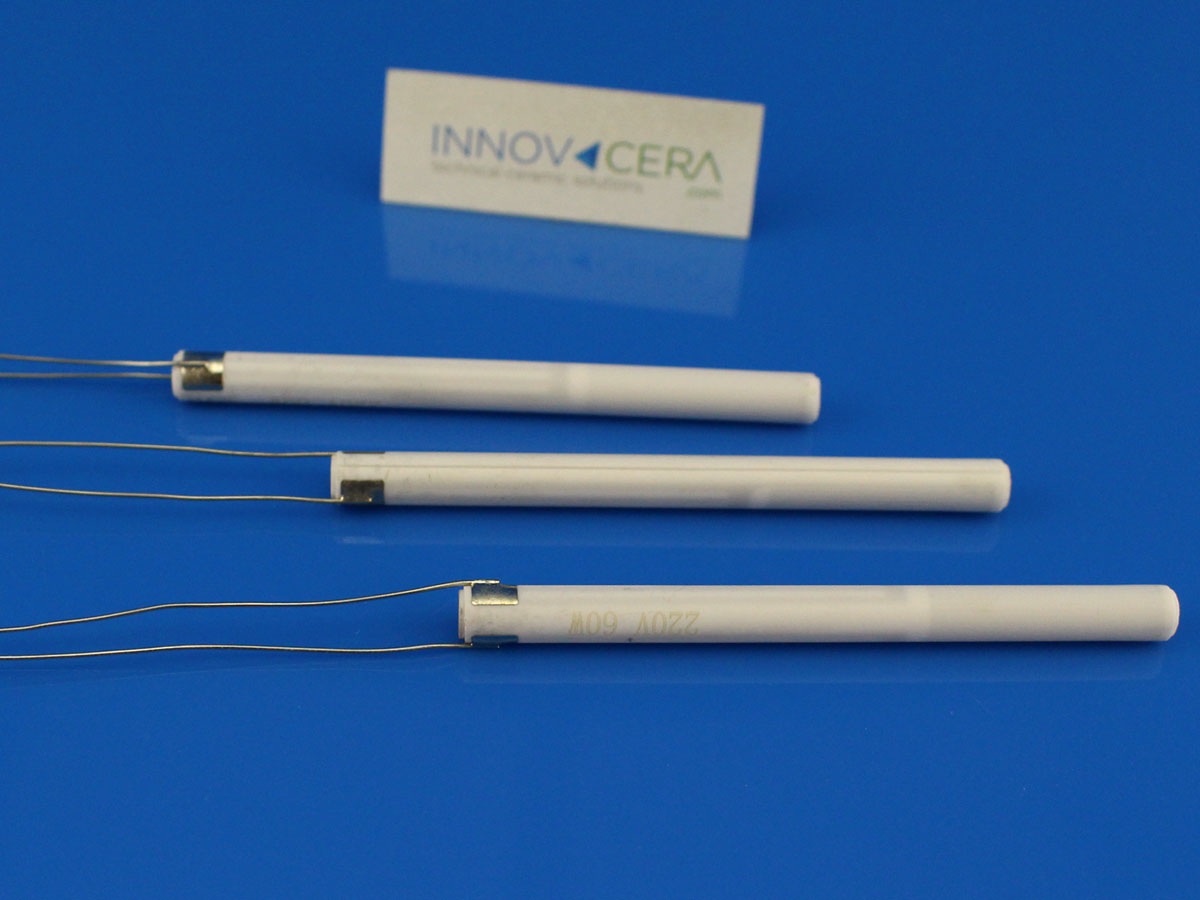

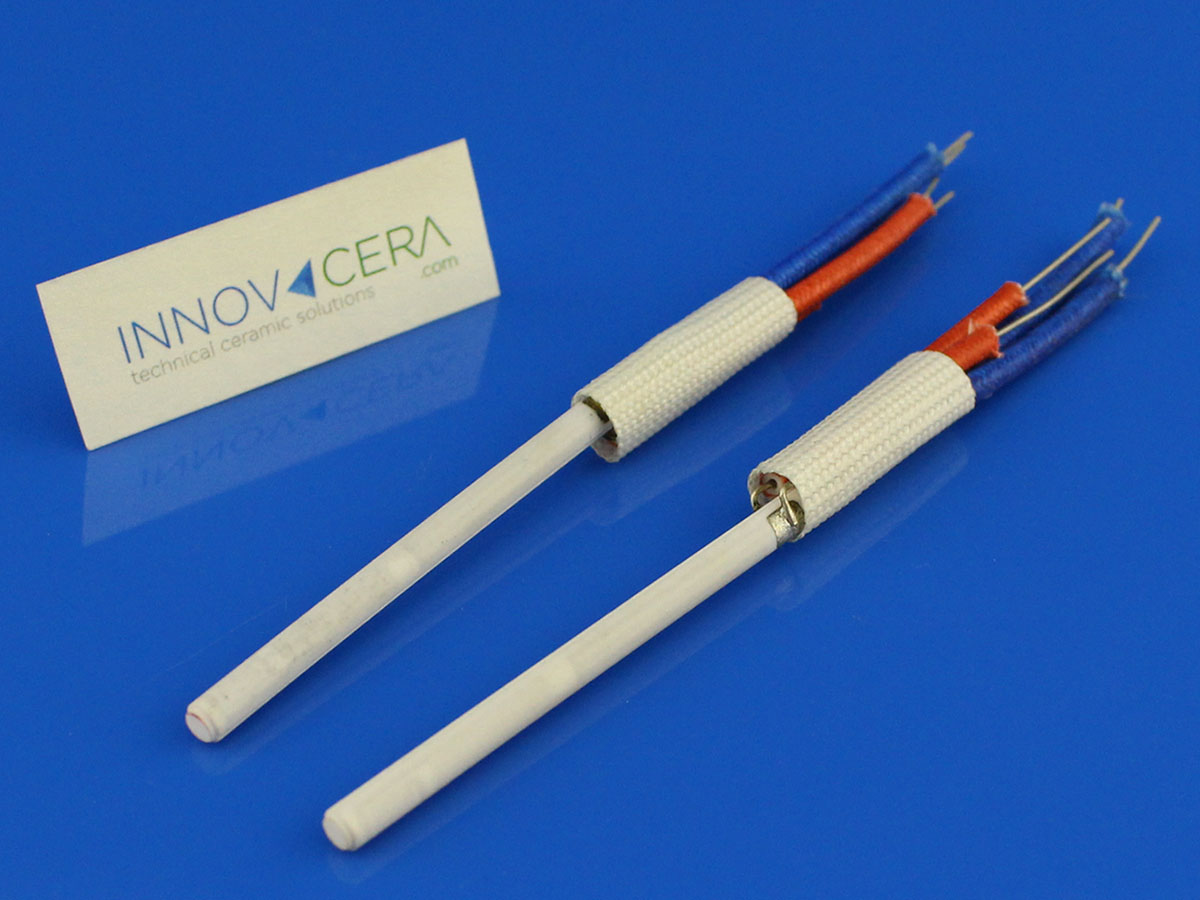

Product Specification

Working: Voltage: 24~220VAC

Heating Resistance: 3Ω~800Ω (23℃±2℃)

Dimension: Length: 30~90mm; Diameter: 3.5~8mm

Electrode: Welding four nickel wires on the surface

If the test environment has no special requirements, the general temperature is 15~35℃, the humidity is 25~80%, and the air pressure is 101.3kPa~106kPa.

Property

Excellent Mechanical Properties

High-Temperature Durability

Rapid-Heat Up

High-Efficiency Heat Exchange

Small Size/High Output

Features:

Compact, Light-Weight, and Energy-Conserving

- High watt density, good thermal efficiency

- Laying of multiple heating elements per unit is available

Superior Thermal Properties

- Rapid heat increase

- Custom designed temperature distribution available

- High levels of insulation allow direct contact with water, kerosene, and metal

High Reliability

- Superior dielectric strength and electrical insulation

- Longer life due to oxidation-proof design on resistivity material

- Superior chemical resistance

Handling and notices of using the ceramic heater

- Don’t give the ceramic heater impact like falling down to the ground or strike it hammer forcefully.

- Using ceramic heater at rating voltage. High voltage may cause damage to the ceramic heater.

- The temperature control device should be used on a ceramic heater. And the surface temperature of the ceramic heater should no more than 800℃ since the temperature is closely related to its working life.

- Don’t use the ceramic heater on the following conditions: quick heat up, a quick cool down, and uneven heat distribution because of the above conditions, open circuit. Racking problems may happen. Please be careful of heat shock besides other situations that are not mentioned here, such as incomplete contact with a metal part that will also cause uneven heat distribution.

- Don’t put excess strength to Ni-Wire and brazing area… If Ni wires were bent many times, power concentration points would become brittle. Crack even breakage may happen. If pulled Ni wires with excess power, the brazing area will be peeled off.

- Don’t use the ceramic heater for medical, nuclear, and aero purposes.