Micropores in ceramics can be used in many critical applications, to fulfill specific functions, one of which is filtration or separation.

Microporous ceramics can filter and separate like most other microporous substances. It can pass liquid or gas through a porous material, and separating, removing, and collecting particulate matter from suspended solids and suspended substances (fine particles, microbes, polymer molecules, mist, aerosol, etc.) from the fluid. Microporous ceramics are used in the process is called a “filter”.

Supply industries include:

Filtration in aquaculture, chemical industry, light industry, biology, medicine, food, beverage, and other industries

Materials:

- Porous ceramics are made by alumina and silicon carbide

- Pore sizes are from 1um to 200um, Porosity rate: 30~55%

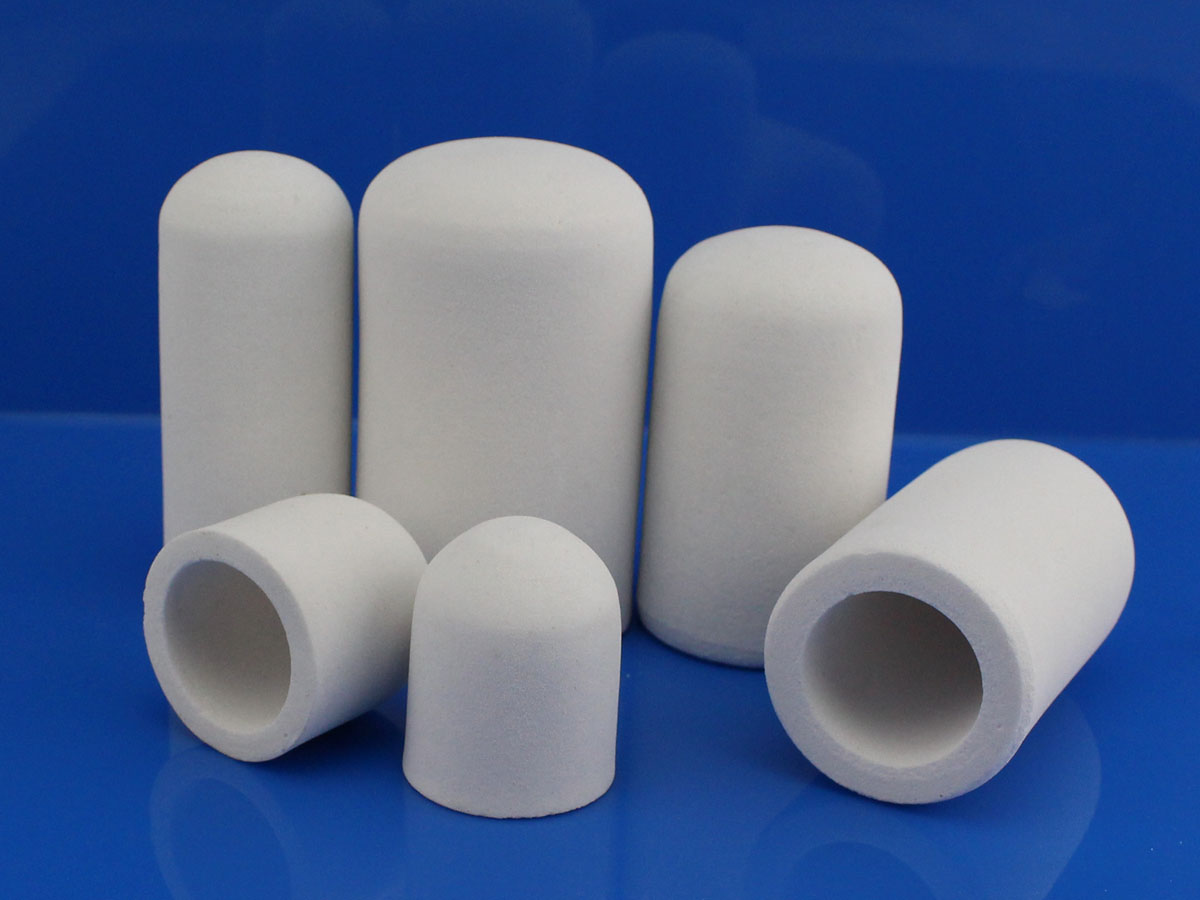

- The geometry of the ceramic filter elements ranges from cylinders, sleeves, plates, cassettes, disks, mono and multi-channel pipes up to honeycomb or foam structures

- Custom size is available for us

Common Benefits:

- Controlled pore size, porosity, and permeability

- Adsorption and breathability

- Chemically inert – Corrosion resistance

- Environmental compatibility and biocompatibility

- High-Temperature capability to 1000ºC

- Range of standard element sizes

Typical Applications for Gas and Air Filtration:

- Hot Gas Filtration

- Precoat Filtration

- Dust and Fume Filtration

- Compressed Air Filtration

- Aeration, air distribution, and inflation disperse the gas into the liquid

- Air and steam disinfection and filtration

Typical Applications for Liquid Filtration:

- Industrial Waste Water Treatment

- Filtration for chemical processing plant

- Paper and cardboard processing

- Solvent filtration

- Precoat filtration

- Liquid backwash

- Filtration of corrosive fluids

- Oil filtration