Porous ceramic itself has numerous pores by the ceramic sintering technology and is used for a vacuum chuck. It can serve as an air flotation platform, widely used in semiconductor, panel, laser process, and non-contact linear slide.

Absorb or float the workpiece by applying positive and negative pressure gas, the workpieces include wafer, glass, PET film, or other thin objects.

Application principle:

The airflow with negative vacuum pressure is set to enter the ceramic, the workpiece can be adsorbed.

The airflow with positive vacuum pressure is set to go out of the ceramic, the part can be blown up or not contact the ceramic.

Materials:

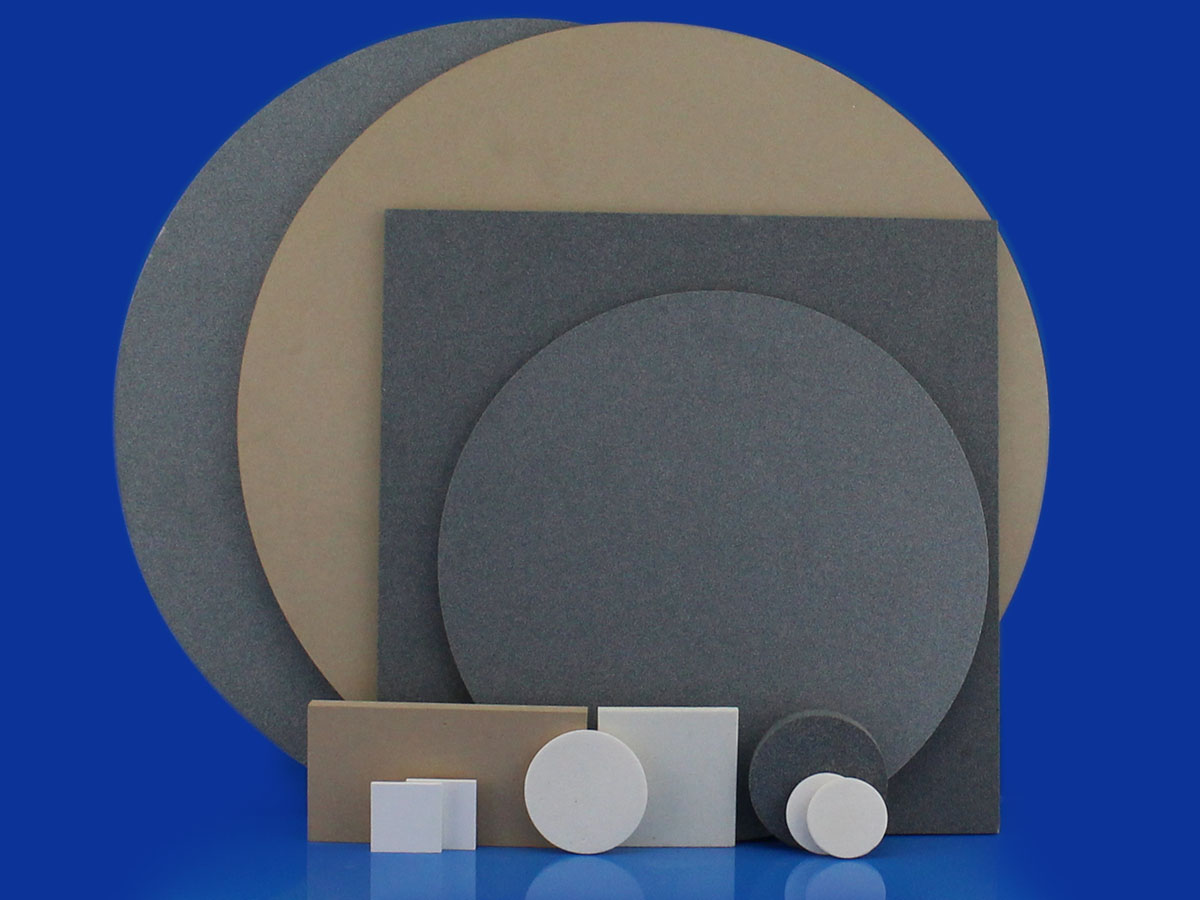

-Porous ceramics are made by alumina and silicon carbide, color includes white, light brown, dark brown, blue-gray

-6″, 8″, 12″ regular size available in round, square, oval shape or irregular shapes and sizes.

-Pore size includes 15um, 30um, 40um, 50um, 100um.

-Custom size is available for us

Characteristics include:

- High flatness and parallelism

- Compact and uniform microstructure with high strength

- Good permeability and uniform adsorption affinity

- Long lifetime

- Dressing easily

Different types of Vacuum Chuck Table:

- Thinning Chucks

- Dicing Chucks

- Cleaning Chucks

- Transportation Chucks

- Printing Chucks

- Custom is available

Service

New and refurbished porous ceramic chucks for Disco, ADT, K&S, Applied materials TSK, OKAMOTO, Micro Automation, Load Point, etc dicing saws and grinders.