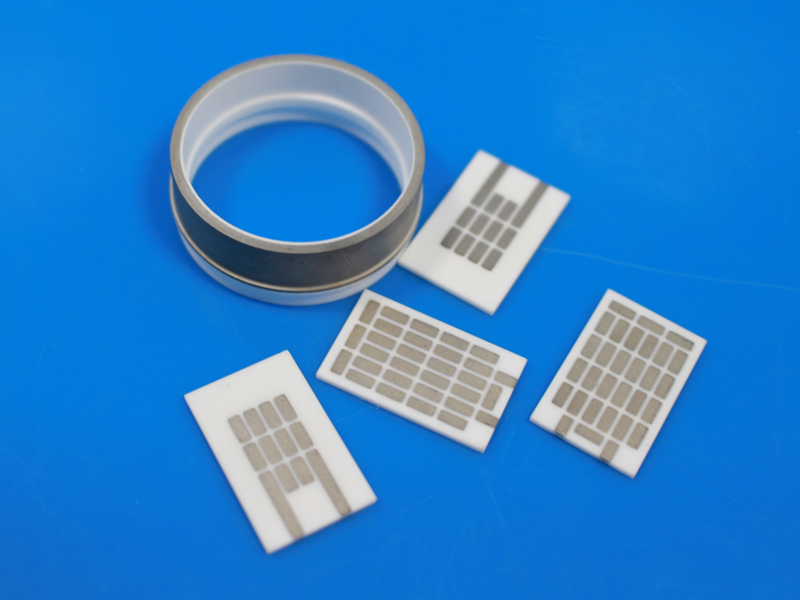

Beryllium Oxide (BeO) Ceramics, which is commonly referred to as beryllia ceramics. BEO ceramic substrates are made of more than 99% beryllium oxide ceramics. The ceramic substrate is based on the electronic ceramic, with the membrane circuit element outside and the fitting element to form a support base for the sheet material. Beryllium Oxide Ceramic substrates thermal conductivity is more than 230 W/Mk, so it is widely used for Advanced LED Ceramic Modular Technology which requests very high thermal conductivity.

Beryllium oxide ceramic substrate advantages:

- High melting point

- Low dielectric constant

- High electrical resistivity

- Thermal shock resistance

- Easy and effective metallization

- More consistent heat dissipation

- Low coefficients of thermal expansion

- Better uniformity of crystalline structure

- Superior thermal conductivity(equivalent to aluminum)

- More durable in semiconductor chamber cleaning environments

Beryllium oxide ceramics are one of the most important and necessary basic materials for electric vacuum devices, power electronic modules, especially high-power microelectronic devices. The application is as below:

- Nuclear Reactors

- High power electronics

- Semiconductor processing

- Avionics conversion circuits

- Microwave communications

- Transmitters for radio frequency

- Oil and gas exploration equipment

- Long-range fiber optic transmission

- Medical Industry such as eye surgery

- Magnetic resonance imaging machines

- Missile guidance systems in the military industry

- Industrial laser metal-cutting and marking equipment

- Airplane and satellite communications systems in the aerospace field